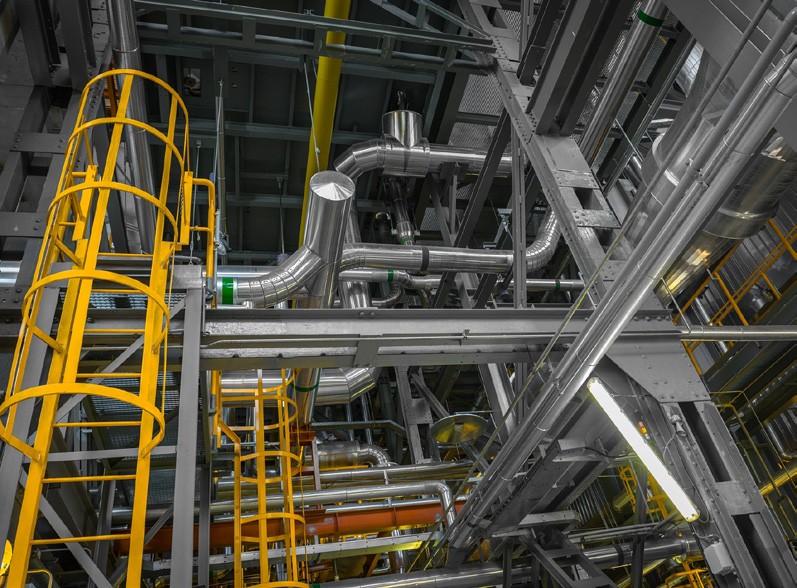

The fabrication of the ladder will be standard (QCS) or as per the client needed. This is fabricated from pultruded square tubes and rounded rungs. The ladder stringer is fabricated using 50x50mm square tube and the rungs are 32mm serrated hollow tube. The rungs shall be provided at the distance of 300mm center to center. The surface of each rung has an anti-skid surface to prevent slippage when stepping on it.

The stand off brackets are provided for suitable fixing with any structure using stainless steel anchor and are fixed withthe stringer using stainless steel nuts and bolts with a maximum distance of 1200mm for each bracket.

Ladders with safety cage are available as per the requirement. These cages starts from a maximum clear distance of 2100mm from the ground. The total width will be 750mm with safety cage and 400mm without safety cage.

Ladder design and manufactured as per the standards mentioned below:

• EN131 is for trade and light industrial use.

• BS2037/BS1129 Class 1 are for heavy duty and industrial use.

• BS2037/BS1129 Class 3 is for domestic use.

• ASTM E08-84 - "Test for Surface Burning Characteristics of Building Materials"

Pultruded fiber reinforced composites are the best performing composite materials. The technology applied here ensures best product output with

excellent physical characteristics.

The Pultrusion process is a proven manufacturing method for obtaining high quality FRP profiles with consistently repeatable mechanical properties.

CORROSION RESISTANT

Requires less maintenance. No rust, peeling of flaking and will continue to

maintain structural integrity over time.

STRONG & LIGHTWEIGHT

Up to 70% lighter than steel, concrete or wood with an exceptional

strength-toweight ratio.

ELECTRICALLY & THERMALLY NON-CONDUCTIVE

It is electrically non-conductive leading to increased safety compared to

conductive materials (i.e., metal). FRP also has low

thermal conductivity (heat transfer occurs at a lower rate), resulting in a

more comfortable product surface when physical contact occurs

LOW INSTALLATION COST

Easy to cut and can be installed easily with nuts and bolts. Welding or

hot work is not necessary. Installation can be done without using heavy

equipment and machinery, requiring less manpower.

MAINTENANCE FREE

The durability and corrosion resistance of GRP and pultruded

gratings and other products reduce or eliminate need for heavy maintenance

like

sandblasting,

scraping and painting. In fact,

most

GRP products

are

easily

cleaned

with a high-pressure washer.

FLEXIBILITY IN DESIGN

Manufactured to your individual specifications.

SAFETY

Slip resistant footing in wet and oily environments can increase safety for

workers which lead to fewer workplace accidents and a reduction of injury

associated costs.